Media & Technology

Western Magnesium Corp (OTCMKTS: MLYF) Powerful Runner as Magnesium Pioneer Looks to Become the World’s Low-Cost Producer of Green, Pure Magnesium

Published

3 years agoon

By

Boe Rimes

Western Magnesium Corp (OTCMKTS: MLYF) is making a historic rise up the charts in recent months from well under a dime to recent highs near $1 mark. MLYF is quickly emerging as a volume leader in small caps attraction legions of new shareholders including some heavy hitters on the OTC. Currently under heavy accumulation MLYF is moving steadily northbound with many new investors buying in every day. The stock is a powerhouse and continues to move northbound with strength and purpose.

The Company is focused on becoming the become world’s low-cost producer of eco-friendly, high-quality magnesium. MLYF has created a proprietary technology which creates a purer form of magnesium in contrast to the Pidgeon process which results in a less pure magnesium. Western Magnesium has just completed the buildout its magnesium reactor. This is a significant, and much anticipated milestone for the Company. Executive Chairman, Mr. Ed Lee, states “This reactor unit is a significant step forward that will enable the Company to enter the marketplace with its proprietary continuous condenser, and will secure Western Magnesium’s future for decades to come.” Initial metal production will allow management to work closely with end users in the automotive, aerospace, and ecofriendly technology companies and the Department of Defense to assess the amount of metal needed for their assembly line manufacturing, and the form in which they will need the metal.

Western Magnesium Corp (OTCMKTS: MLYF) (TSXV:WMG) (Frankfurt-3WM) goal is to be a low-cost producer of green, primary magnesium metal, a strategic commodity prized for its strength and light weight. Unlike outdated and costly production processes, Western Magnesium looks to use a continuous silicothermic process to produce 99.9% pure magnesium, which significantly reduces labor and energy costs relative to current methods and processes, while being environmentally friendly. Technology is at the heart of Western Magnesium’s business and is the result of 10 years of stealth research and development done at its original location in British Columbia, Canada. The Company’s R&D team consists of world leading authorities in magnesium production and expertise as well as research from as early as post-WWII U.S. magnesium production; when America led the industry. The Company has been raising money in several private placements and offerings in recent months for proceeds of well over $5 million usd.

Western Magnesium Corp (OTCMKTS: MLYF) (TSXV:WMG) (Frankfurt-3WM) goal is to be a low-cost producer of green, primary magnesium metal, a strategic commodity prized for its strength and light weight. Unlike outdated and costly production processes, Western Magnesium looks to use a continuous silicothermic process to produce 99.9% pure magnesium, which significantly reduces labor and energy costs relative to current methods and processes, while being environmentally friendly. Technology is at the heart of Western Magnesium’s business and is the result of 10 years of stealth research and development done at its original location in British Columbia, Canada. The Company’s R&D team consists of world leading authorities in magnesium production and expertise as well as research from as early as post-WWII U.S. magnesium production; when America led the industry. The Company has been raising money in several private placements and offerings in recent months for proceeds of well over $5 million usd.

MLYF has created a proprietary technology which creates a purer form of magnesium in contrast to the Pidgeon process which results in a less pure magnesium. The Company’s technology overcomes the inefficiency of current production methods that require large quantities of resources, are time consuming, high-risk, and very labor intensive. MLYF proprietary technology utilizes a continuous silicothermic process to produce (99.8%) pure magnesium. The process begins with mined dolomite (calcium-magnesium carbonate), which is crushed and calcined (thermal decomposition) to make Magnesium Oxide (MgO). The MgO is combined with ferrosilicon, a reductant and a catalyst, and formed into briquettes. The briquettes are fed into the newly designed continuous reactor, where they are heated. This allows the silicon to react with oxygen and reduce the magnesium to metal. The vaporized Mg is collected and removed using a proprietary Mg-recovery system designed specifically for this process as molten Mg. The Company’s uses significantly less energy as nature eliminates the temperature cycles. The company uses electric-powered calciner, heat-recovery systems and a method for recovering CO2 from the calcination step which further reduces the environmental footprint and raises efficiency.

https://twitter.com/PennyHo9/status/1422605477997912064

https://twitter.com/JrMagnesium/status/1422734425981296641

To Find out the inside Scoop on MLYF Subscribe to Microcapdaily.com Right Now by entering your Email in the box below

Western Magnesium has recently completed the buildout its magnesium reactor. This is a significant, and much anticipated milestone for the Company, and has accelerated the Company’s internal timeline for the production of magnesium metal. As we have previously focused on metal production by the end of 2021. Testing will commence within the next 30 days, on its proprietary new reactor. Management is pleased with the progress to date and is excited to commence this next phase. Currently the commercialized pilot plant is undergoing the final build out stage and all necessary equipment and supplies have been finalized and ordered, allowing the operations team to produce an updated baseline schedule. Management and staff have been working diligently to expedite this testing phase and we are confident that we will be able to commence production with the new timeline. Ancillary feed equipment has arrived at the facility and has begun operating, allowing the operations team to begin optimizing the feed material composition and size.

Western Magnesium has recently completed the buildout its magnesium reactor. This is a significant, and much anticipated milestone for the Company, and has accelerated the Company’s internal timeline for the production of magnesium metal. As we have previously focused on metal production by the end of 2021. Testing will commence within the next 30 days, on its proprietary new reactor. Management is pleased with the progress to date and is excited to commence this next phase. Currently the commercialized pilot plant is undergoing the final build out stage and all necessary equipment and supplies have been finalized and ordered, allowing the operations team to produce an updated baseline schedule. Management and staff have been working diligently to expedite this testing phase and we are confident that we will be able to commence production with the new timeline. Ancillary feed equipment has arrived at the facility and has begun operating, allowing the operations team to begin optimizing the feed material composition and size.

This furnace will be the first of its kind, and a major step towards being able to operate a silicothermic reactor system from open atmosphere to a sealed vacuum space on a continuous basis. This is very disruptive technology with controllable parameters from an efficiency, energy, and environmental standpoint. A continuous internally heated reduction furnace of this nature coupled with the proprietary Western Magnesium condenser will allow for maximum continuous production from pit or stockpile, to magnesium metal, to the end-user in timely manner. A process that assembly line manufacturers have longed for.

A third lighter than aluminum, 60% lighter than titanium and 75% lighter than steel, magnesium’s strength and castability has made it an obvious replacement for any component that needs to be lighter and stronger. As the lightest of all structural metals, magnesium metal has been used strategically in key components in automotive, defense and aeronautics since World War II.

Executive Chairman, Mr. Ed Lee, states “This reactor unit is a significant step forward that will enable the Company to enter the marketplace with its proprietary continuous condenser, and will secure Western Magnesium’s future for decades to come.” Initial metal production will allow management to work closely with end users in the automotive, aerospace, and ecofriendly technology companies and the Department of Defense to assess the amount of metal needed for their assembly line manufacturing, and the form in which they will need the metal.

Magnesium prices are rising due to tight supplies from China, by far the world’s largest producer of the rare-earth metal, and brisk demand from the auto industry. Magnesium is mainly used in alloys to strengthen aluminum. While demand for magnesium is growing as automakers work to make their cars lighter, it is also expected to be used in new types of batteries for electric vehicles; according to a report from grandviewresearch.com the global metal magnesium market size was valued at USD 3.5 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 8.8% from 2020 to 2027. Increasing die casting requirements in automotive and various structural applications is projected to assist in the growth of the market for metal magnesium. Magnesium is one of the lightest materials and has an excellent strength to weight ratio. It has high thermal and electrical conductivity and the ability to withstand high operating temperatures. Magnesium alloyed with aluminum is used in various applications including vehicle parts, RFI and EMI shielding, electrical housings, and electrical connectors. Magnesium is critical to the manufacture of car seats, batteries, laptops, plane seats, cell phones, power tools, and auto parts.

$MLYF Strong like Bull…. pic.twitter.com/W56NTK1EA0

— BigWorm (@Unclebuck2323) August 6, 2021

For more on MLYF Subscribe Right Now!

Western Magnesium Corp (OTCMKTS: MLYF) is making a historic rise up the charts in recent months from well under a dime to recent highs near $1 mark. MLYF is quickly emerging as a volume leader in small caps attraction legions of new shareholders including some heavy hitters on the OTC. Currently under heavy accumulation MLYF is moving steadily northbound with many new investors buying in every day. The stock is a powerhouse and continues to move northbound with strength and purpose. The Company is focused on becoming the become world’s low-cost producer of eco-friendly, high-quality magnesium. MLYF has created a proprietary technology which creates a purer form of magnesium in contrast to the Pidgeon process which results in a less pure magnesium. Western Magnesium has just completed the buildout its magnesium reactor. This is a significant, and much anticipated milestone for the Company. Executive Chairman, Mr. Ed Lee, states “This reactor unit is a significant step forward that will enable the Company to enter the marketplace with its proprietary continuous condenser, and will secure Western Magnesium’s future for decades to come.” Initial metal production will allow management to work closely with end users in the automotive, aerospace, and ecofriendly technology companies and the Department of Defense to assess the amount of metal needed for their assembly line manufacturing, and the form in which they will need the metal. Magnesium prices are rising due to tight supplies from China, by far the world’s largest producer of the rare-earth metal, and brisk demand from the auto industry. Magnesium is mainly used in alloys to strengthen aluminum. While demand for magnesium is growing as automakers work to make their cars lighter, it is also expected to be used in new types of batteries for electric vehicles. We will be updating on MLYF when more details emerge so make sure you are subscribed to Microcapdaily so you know what’s going on with MLYF.

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

Disclosure: we hold no position in MLYF either long or short and we have not been compensated for this article.

You may like

Featured

Meta Materials (NASDAQ: MMAT): More Due Diligence and Exploring Latest Developments

Published

6 months agoon

January 16, 2024

Meta Materials (NASDAQ: MMAT) witnessed a significant uptick in trading activity on January 16th, 2024, resulting in a notable 20% increase in its stock value by market close. Intrigued by this surge, we explored various sources, including press releases, SEC filings, and social media, to identify the catalyst behind this sudden gain.

Unexpectedly our research revealed no recent material releases. Instead, the surge seems tied to an announcement from a few days ago that didn’t grab much attention at first. As time passed, it started generating more buzz but there’s still a lot more to dig into and a number of ideas to consider for today’s rally.

If you haven’t caught up on our previous analyses of MMAT, you can find the overview here. In this report, we aim to explore the cause-and-effect dynamics of recent events, offering insights that might illuminate expectations for Meta Materials in the near future.

Background:

If you’re new to MMAT or haven’t been a long-time follower, let’s kick things off with a quick intro to the company.

Meta Materials stands at the forefront of advanced materials and nanotechnology. Their focus is on pioneering novel products and technologies utilizing sustainable and innovative scientific approaches. The interesting part is their advanced materials have the transformative power to enhance a variety of common products, infusing them with heightened intelligence and sustainability.

Leveraging its technology platforms, they’re capable of empowering global brands in creating cutting-edge products that elevate overall performance.

Their technology has application across multiple industries including aerospace and defense, consumer electronics, 5G communications, batteries, authentication, automotive, and clean energy. Their agreement with Panasonic is certainly a great start to empowering their growth in one of many verticals. Overall the TAM is ~$32B and with current growth rates, it’ll increase to a whopping ~$61B by 2026.

MMAT’s goal is to shape a smarter and more sustainable world. If you look through their presentation, you can continue to evaluate the many ways their technology transforms everyday lives. We highly suggest you take a look.

Additional Resources:

- @LauraLoomer’s video on MMAT

- @metaheadj’s post on X, displaying Rob Stone‘s response update for an investor

Subscribe to Microcapdaily.com Right Now by entering your Email in the box below.

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

What Happened:

So, MMAT issued a press release on January 11th, 2024, announcing a proposed settlement with the Securities and Exchange Commission (SEC) concerning an investigation related to the Torchlight Energy Resources, Inc. and Metamaterial Inc. merger.

According to the release, The company has extended a settlement offer (Proposed SEC Settlement) to the SEC’s Division of Enforcement. This proposed settlement aims to address concerns regarding antifraud, reporting, books and records, and internal accounting control provisions of securities laws. It is important to note that the Proposed SEC Settlement is contingent on approval by the SEC Commissioners, and the company cannot predict the approval timeline.

If accepted, the Proposed SEC Settlement would involve the SEC entering a cease-and-desist order and the company paying a civil money penalty of $1 million over a one-year period in four installments. Notably, the company would neither admit nor deny the findings outlined in the Order.

The company’s board of directors and management team view the Proposed SEC Settlement as beneficial for shareholders. If approved, it is expected to remove uncertainty surrounding the investigation, enabling the company to focus on advancing its business objectives.

So What:

If you’ve just read through the announcement and are confused, you’re not alone. It appears that many investors may have mis-read the press release, thinking that the SEC was being punished and MMAT was reaching a settlement agreement, but it appears to be the other way around.

In the event of approval, the company is obligated to pay a civil money penalty of $1 million. This penalty would be paid in four installments over the course of one year, following an agreed-upon payment plan. However, the PR also notes that the company cannot predict with certainty whether or when the Proposed SEC Settlement will even be approved by the SEC Commissioners.

According to another user on X, @AShortSqueeze, MMAT’s initial analysis has potentially revealed the motherload of counterfeit shares.

But if you scroll through the comments, you’ll see other users pointing out that this information is actually old news. This is just one of many widely circulated posts that might have been misunderstood.

Significant Coverage:

Another theory suggests that a notable influencer in the financial space, @MoonMarket_, has set their sights on the company and is conducting additional due diligence. With a substantial following of almost 75K users, the influencer’s involvement could have contributed to a significant fluctuation in today’s trading session. It’s important to recognize that X is packed with plenty of financial influencers, and blindly following their moves can be risky. Many are involved in day trades, momentum trading, or at least contemplating such strategies.

Conclusion:

The buzz around MMAT today seems fuelled by a mix of misrepresented themes and recycled news, creating the illusion of fresh, imminent developments.

As per usual, the magnitude of MMAT’s technology and potential integrations across various verticals continues to create a roar of excitement. On another front, we’re also continuing to see speculation about a short squeeze due to substantial amounts of counterfeit shares.

For now, patience is key and we suggest closely monitoring developments. MMAT especially tends to be quite volatile.

Disclosure: We have not been compensated for this article/video. MicroCap Daily is not an investment advisor; this article/video does not provide investment advice. Always do your research, make your own investment decisions, or consult with your nearest financial advisor. This article/video is not a solicitation or recommendation to buy, sell, or hold securities. This article/video is our opinion, is meant for informational and educational purposes only, and does not provide investment advice. Past performance is not indicative of future performance.

Picture by StartupStockPhotos from Pixabay

Featured

Meta Materials’ (NASDAQ:MMAT) Journey: Legal Hurdles, Innovation and Future Potential

Published

10 months agoon

October 13, 2023

Meta Materials (NASDAQ: MMAT) has been a hot topic as of late, with investors all over the web talking about a potential resurgence. If we rewind to late 2020 and glance at their stock chart, we witness an impressive surge from ~$0.54 to a peak of $13.52, an astonishing 2400% gain within’ the span of a few months. If you’ve been following our articles lately, you’ll notice a similar kind of performance from Tempest Therapeutics’ (NASDAQ: TPST). This is of course a rare event, but there’s a noteworthy angle to consider. While TPST’s initial data release triggered a significant surge, what propelled it further appears to be its “Poison pill” strategy. Recent tweets from MMAT’s CEO suggest a similar strategy is in the works. Could MMAT experience a colossal gain reminiscent of 2021 or even rival TPST’s performance? Let’s delve into Meta Materials, its recent developments, and potential prospects to uncover what’s in store.

Background:

Meta Materials stands at the forefront of advanced materials and nanotechnology. Their focus is on pioneering novel products and technologies utilizing sustainable and innovative scientific approaches. The interesting part is their advanced materials have the transformative power to enhance common products, infusing them with heightened intelligence and sustainability. Leveraging its technology platforms, they’re capable of empowering global brands in creating cutting-edge products that elevate overall performance. Their technology has application across multiple industries including aerospace and defense, consumer electronics, 5G communications, batteries, authentication, automotive, and clean energy. Overall, that’s ~$32B TAM and with current growth rates, it’ll increase to a whopping ~$61B TAM by 2026. Their goal is to shape a smarter and more sustainable world. If you look through their presentation, there are a number of ways their technology can transform our everyday lives. We highly suggest you take a look.

Subscribe to Microcapdaily.com Right Now by entering your Email in the box below.

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

Lawsuits:

You’ll notice MMAT has faced a challenging year as its valuation took a hit following the initiation of two separate class action lawsuits that stemmed from a short-seller report and statements related to Meta’s business combination with Torchlight Energy Resources.

We’ll keep this section short and focus on the accusations related to the business combination. If you’d like more information on the short seller lawsuit, click here.

Long story short, a shareholder filed a class action lawsuit against Meta on behalf of individuals who acquired the company’s publicly traded securities between September 20, 2020, and December 14, 2021. The lawsuit alleged violations of the Securities Exchange Act of 1934. The complaint outlined that Meta Materials, initially known as Torchlight Energy Resources, Inc., exaggerated its business connections, product capabilities, and pricing during its merger with Metamaterial Inc. The filing highlighted a subsequent SEC subpoena, leading to a share price drop. Additionally, a critical report by Kerrisdale Capital triggered another significant share price decline, further impacting investors.

However 11 days ago on October 2nd, 2023, there were significant positive developments regarding this situation. It appears that MMAT will no longer have this legal burden to bear. The lawsuits were entirely dropped, and the court ruled to dismiss all the allegations made against them. As you might of noticed, the initial announcement earlier this year led to a huge selloff. At the current moment, it’s trading at extremely low levels and many online believe there’s substantial upside.

Poison Pill:

As we previously mentioned, it appears the CEO, George Palikaras is working on a poison pill of his own. After Tempest Therapeutics (NASDAQ: TPST) released their latest data it brought ~2400% gain, but their poison pill managed to push that gain even further to ~4000%. If you’re not familiar with what a poison pill is, allow us to explain below.

A poison pill is a defensive strategy used by a company’s management to deter or prevent hostile takeovers or acquisitions by another entity. The term “poison pill” implies that it is intended to be unattractive or undesirable for the acquiring entity.

Typically, a poison pill involves issuing new shares or other financial instruments to existing shareholders, or allowing them to purchase shares at a significant discount, in the event that an outside entity acquires a certain percentage of the company’s shares. This dilutes the ownership and voting power of the acquiring entity, making the takeover more difficult or costly.

The objective is to make the acquisition financially less appealing or more difficult, encouraging potential acquirers to negotiate with the company’s board of directors instead of pursuing a hostile takeover.

Palikara just recently tweeted, “Revenue, strategic partnerships, cost efficiencies, hiring & paying for performance, non-dilutive capital, poison pill, relentless work, Revenue… Plenty of time 2 get in compliance, but our bar is set a lot higher than that.”

If you look through some of MMAT’s latest releases, you’ll notice they’ve announced various forms of funding, more recently they closed a financing for 50M with Lincoln Park Capital Fund, LLC.

Subscribe to Microcapdaily.com Right Now by entering your Email in the box below.

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

Potential Application & Outlook:

Pay special attention to this section, as we’ll be spotlighting potential applications of MMAT’s technology and where they’re at in the commercialization process. Many believe the application alone could hold substantial returns for long-term shareholders.

One user from Twitter, @Seashellpants, has shared a video that outlines in great detail MMAT’s agreement with the Simon Fraser university, one of the top universities in Canada and worldwide.

In this video, we’ll catch a glimpse of how the R&D process is going so far and potential application across various verticals. You’ll need to be cautious, as this video may cause “Heavy breathing”.

We’ll provide a brief summary below, but don’t miss out on the hyperlink above. It’s not only entertaining, but also packed with valuable insights.

Breakdown of the Video:

Just over 2 years ago on October 5th, 2021 MMAT acquired Nanotech Security Corp. which is now considered a subsidiary of MMAT. If we delve into MMAT’s 10Q from May 12th, 2023, there are multiple updates on how their research is going with the Simon Fraser University. Within this 10Q we also find an interview with the CTO, Clint Landrock, who unveils numerous case studies related to their nano-manufacturing commercialization efforts.

First and foremost, MMAT has been granted a parent-patent that includes it’s claim for nano-hole structures and applications for those features in the security and authentication industry. It also includes claims for the use of those nano-scale structures that are smaller than a wavelength of light in conjunction with printable electronic components, which would include electronic displays, batteries and solar cells.

Landrock states,”It seems like it could be used for a range of possible markets, including games and interactive displays for consumer products”. He even touches on how these displays could be used for specific light wave optical guides used in medical programs for sensing bacteria and disease or for drug application.

If we delve deeper, the initial purpose of this technology was to enhance solar panels by maximizing electron production, leading to more efficient and durable batteries. Considering their nano-scale structures are tinier than a wavelength of light, you can envision the implications for battery performance. Especially in the context of the ongoing global shift towards Electric Vehicles (EVs), this presents a significant opportunity to integrate such a groundbreaking technology.

However, given the immense demand for this technology across various applications, achieving scalability is critical, necessitating a roll-to-roll manufacturing approach to handle the high volume needed. Typically, scaling up can pose a significant hurdle, but what amplifies the excitement here is Landrock’s affirmation that they have effectively demonstrated, in collaboration with a third party, the ability to produce and operate their technology using high-speed roll-to-roll casting machines. The outcomes were remarkably positive with 100% through-put yield. Which means 100% of the images produced could be used for commercial purposes.

Another common barrier to entry is the costs associated with scaling a new technology. To make things even better, their technology also aligns with global initiative to be more green. Landrock states, “Also, this is a true green technology that will not harm the environment, costs less to produce than the current technology and provides far improved security for authentication requirements”.

Subscribe to Microcapdaily.com Right Now by entering your Email in the box below.

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

Agreement with Panasonic:

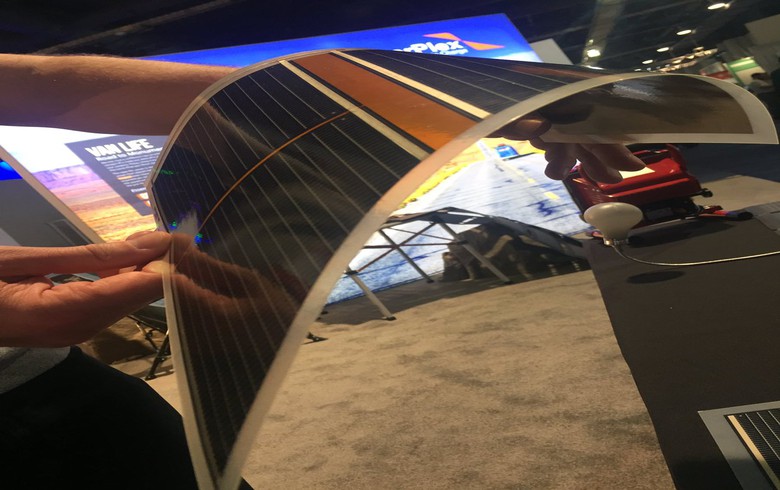

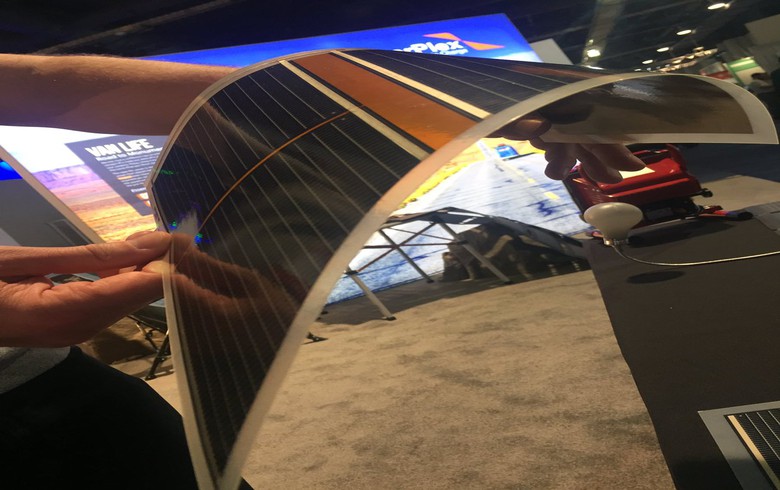

On September 29th, 2023 MMAT teamed up with Panasonic Industry Co. (An operating company in charge of device business within the Panasonic Group) to advance transparent conductive materials. This collaboration aims to enhance the supply of NANOWEB® films, which would benefit sectors like automotive and consumer electronics, transparent film antennas, heaters, and electromagnetic shielding.

The demand for ultra-low sheet resistance and high optical performance is increasing, particularly for flexible solar cells and smart windows. According to BCC Research, the global transparent conductive films market is projected to reach $7.6 billion by 2025 from $4.9 billion in 2020, growing at a CAGR of 9.2%.

George Palikaras, CEO of META, highlighted the importance of this collaboration, emphasizing their shared goal to advance transparent conductive materials. Panasonic Industry has a track record of mass-producing quality transparent conductive films, making them a strategic partner for META.

Yuichi Yoshikawa, Director of Touch Solutions Business Unit at Panasonic Industry, expressed excitement about the collaboration, foreseeing it providing advanced solutions and creating new possibilities across various applications.

This collaboration merges NANOWEB® metal mesh designs by META with Panasonic Industry’s cutting-edge process technology, aiming to set new industry standards. They will showcase their collaborative solutions at CEATEC 2023 which goes from Oct 17 – Oct 20 to demonstrate the potential applications of this partnership.

This agreement holds significant weight. Keep a vigilant watch, the event is around the corner and they’re expecting ~200,000 attendees. A collaboration with a well-established and reputable name like Panasonic certainly changes the landscape, and could bring notable shifts for the company in the near future.

Conclusion:

In essence, MMAT stands at a pivotal moment. With the resolution of lawsuits, it appears things could be looking up. Coupled with their recent strategic maneuvers and advancements in commercialization, MMAT certainly holds promise. Could they potentially see a significant valuation upswing in the near term? The consensus among thousands online is yes. Considering the innovation and potential impact, MMAT is undeniably a company worth vigilant monitoring in the months ahead.

We will update you on MMAT when more details emerge, subscribe to Microcapdaily to follow along!

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

Disclosure: We have not been compensated for this article/video. MicroCap Daily is not an investment advisor; this article/video does not provide investment advice. Always do your research, make your own investment decisions, or consult with your nearest financial advisor. This article/video is not a solicitation or recommendation to buy, sell, or hold securities. This article/video is our opinion, is meant for informational and educational purposes only, and does not provide investment advice. Past performance is not indicative of future performance.

Featured

Clean Vision Corporation (OTC: CLNV): Understanding the 180% Surge and Key Insights

Published

10 months agoon

October 6, 2023

Shares of Clean Vision Corporation (OTC: CLNV) have seen an uptrend of 180% since September 18th, 2023. This emerging developer of sustainable clean technology hasn’t had a press release since September 7th, 2023. The company’s seen substantial growth without targeted press releases to update investors. However if you look closer, a deeper narrative emerges. We found a number of SEC filings and there also appears to be a number of notable Twitter users talking about the company, believing it has substantial prospects near term. Before we move forward, let’s pause to gain a deeper understanding of the landscape surrounding Clean Vision.

Background:

Clean Vision is led by Dan Bates, and their goal is to tackle the global plastic waste crisis head-on. Their wholly owned subsidiary, Clean Seas, has developed the Plastic Conversion Network (PCN), a groundbreaking technology aimed at diverting millions of tons of waste plastic from landfills, incineration, and oceans. The PCN converts this plastic feedstock into clean fuels and green hydrogen, significantly reducing reliance on fossil fuels and lowering the carbon footprint.

For a 2 minute overview on the company, we found a great video that CLNV’s subsidiary put together just recently. Feel free to follow this link to watch.

Subscribe to Microcapdaily.com Right Now by entering your Email in the box below.

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

Clean Seas utilizes proven pyrolysis technology to produce environmentally friendly products, which are sold to multinational petrochemical companies, driving the circular plastic economy. Operational PCN facilities are already in place in Morocco and India, with additional conversion facilities in development across West Virginia, Arizona, and Southeast Asia. Long-term feedstock supply agreements exceeding one million tons of waste plastic annually have been secured at no cost.

Furthermore, the company aligns with ESG investment criteria and adheres to five United Nations Sustainable Development Goals (SDGs). Backed by a seasoned management team with extensive experience in sustainability, international development, and finance, Clean Vision is poised to be a key player in the clean energy economy. They invite collaboration to make a significant impact on the global waste plastic problem, striving for a cleaner environment for future generations.

No Press Releases:

Often with OTC companies, it’s common that updates within the company aren’t always accompanied by press releases. If you can’t find press releases, it’s a good practice to search for SEC filings to ensure you haven’t overlooked any important information. There are a number of SEC filings to keep in mind that can be found on CLNV’s IR portal of their website. If you can’t find information on a public issuers website, you can also find anything you need here.

S-1 Filing:

There were a number of filings from August 31, 2023 to October 3rd, 2023 which were mainly related to their S-1 filing. This means the company will likely be up-listing to the NASDAQ. For those that don’t know what this filing is, here’s a brief description:

The S-1 registration statement is a comprehensive document that includes detailed information about the company, its business operations, financials, risks, management team, and the proposed terms of the public offering. It’s a crucial step in the process of conducting an initial public offering (IPO) and making shares available for public trading on major exchanges such as NASDAQ or the New York Stock Exchange (NYSE).

A S-1 registration document is often lengthy and complex, making it challenging for everyday retail investors to grasp. To assist in understanding, we’ve broken down and simplified the initial page of CLNV’s S-1 for you:

CLNV S-1 Filing:

In essence their filing is saying that they are selling a large number of company shares (820,598,246 shares) owned by different people. These shares are part of Clean Vision Corporation, a company based in Nevada.

The people who own these shares can sell them at different times based on certain agreements they had with the company. The agreements are related to three specific dates and are linked to previous investments made by these shareholders.

May Purchase Agreement: This allows the sale of up to 269,042,604 shares based on an investment deal made on May 26, 2023.

February Purchase Agreement: This allows the sale of up to 454,166,752 shares based on an investment deal made on February 17, 2023.

August Purchase Agreement: This allows the sale of up to 97,388,890 shares based on an investment deal made on July 31, 2023.

The company, Clean Vision Corporation, won’t directly make money from the sale of these shares. But if the people who buy these shares decide to use certain options to get more shares, then the company will receive some money. The people selling these shares will handle the costs associated with selling them, like commissions and discounts. The company will handle the paperwork costs associated with registering these shares for sale.

8-K Filing:

It’s also important to note that the company filed an 8-K on October 3rd, 2023 mentioning that on September 26, 2023, Clean Vision Corporation made a deal with an investor. The investor agreed to buy 10,000,000 shares of the company’s common stock for a total of $198,000. The agreement was signed on that day but didn’t take effect until the investor paid the money on September 28, 2023.

As per this deal, the company sold these 10,000,000 shares to the investor at a price of $0.0198 per share. Additionally, the investor received 5,000,000 more shares, but these have restrictions on their sale. The company also has to register these 10,000,000 shares with the U.S. Securities and Exchange Commission within 45 days from the signing date, allowing the investor to sell them in the future.

Twitter Posts:

While exploring online discussions, we found Twitter users @FrankieBstock, @realsheepwolf, and @borders_LLC all showing enthusiasm for Clean Vision’s future potential. Although it’s important to remember that their views aren’t financial advice, it’s encouraging to see how CLNV’s journey has progressed since their initial thoughts on the company.

@realsheepwolf put things into perspective in a simple, comprehensive format for investors to see key takeaways.

“HUGE THINGS HAPPENINGS

✨non-dilutive financing

✨massive revenue growth

✨Morocco India operational

✨WV operational Q-1 2024

✨Arizona operational Q2-Q3 2024

✨Michigan, Mass., Puerto Rico moving toward definitive agreements.

✨Uplisting to NASDAQ”

Following the mentioned individuals, the video showcasing the company’s story above has been widely shared by @FrankieBstock and @borders_LLC.

As the company experiences a surge in daily trading activity another larger user jumped in on the action and took note of the company – expressing surprise at the remarkable increase in trading volume. Specifically, on October 4th, 2023, CLNV achieved a trading volume that equaled nearly $450,000 worth. This is quite significant, especially considering a singular share is being traded for a mere $0.05.

Conclusion:

Clean Vision’s story has garnered significant attention of late, suggesting the possibility of broader recognition among retail traders. It may only be a matter of time before various investment communities direct their focus towards the company. Notably, certain influential users on Twitter, some with a substantial following nearing 20,000 people, are actively discussing the company, adding to its visibility.

However it’s important to note that consistent with their nature, these stocks demonstrate high volatility, carrying the inherent risk of potential loss of your entire investment. Yet, for some, the allure lies in the thrill of potentially substantial returns, akin to the potential behind the roll of dice at a casino.

We will update you on CLNV when more details emerge, subscribe to Microcapdaily to follow along!

Subscribe to Our 100% Free Penny Stock Newsletter. We Have Something Big Coming!

Disclosure: We have not been compensated for this article/video. MicroCap Daily is not an investment advisor; this article/video does not provide investment advice. Always do your research, make your own investment decisions, or consult with your nearest financial advisor. This article/video is not a solicitation or recommendation to buy, sell, or hold securities. This article/video is our opinion, is meant for informational and educational purposes only, and does not provide investment advice. Past performance is not indicative of future performance.

Picture by onehundredseventyfive from Pixabay

Recent Posts

Clean Vision Corp (OTC: CLNV): Overcoming the Plastic Waste Crisis

Meta Materials (NASDAQ: MMAT): More Due Diligence and Exploring Latest Developments

Integrated Cannabis Solutions’ (OTC: IGPK) 633% Surge: Exploring Catalysts, Company Overview, and Growth Potential in 2024

Sonoma Pharmaceuticals (NASDAQ: SNOA): Potential Surge to Speculations – What Lies Ahead?

1847 Holdings (NYSE: EFSH) Soars: Insights, Acquisitions, and What Lies Ahead

Trending

-

Uncategorized2 years ago

Uncategorized2 years agoMeta Materials Inc (OTCMKTS: MMTLP) Enormous Short Position in Trouble as Next Bridge Hydrocarbons Set to Stop Trading (George Palikaras & John Brda on Corporate Action)

-

Micro Cap Insider3 years ago

Micro Cap Insider3 years agoMedium (KOK PLAY) The Parabolic Rise of Metal Arts (OTCMKTS: MTRT)

-

Media & Technology3 years ago

Media & Technology3 years agoHealthier Choices Management Corp. (OTCMKTS: HCMC) Powerful Comeback Brewing as PMI Patent Infringement Lawsuit Moves Forward

-

Media & Technology4 years ago

AMECA Mining RM; the Rise of Southcorp Capital, Inc. (OTCMKTS: STHC)

-

Media & Technology3 years ago

Media & Technology3 years agoSNPW (Sun Pacific Holding Corp) Power Brewing: 50MW solar farm project in Durango Mexico MOU with Atlas Medrecycler 48,000 SF New Partnership Queensland Australia Solar Farm.

-

BioPharma2 years ago

BioPharma2 years agoAsia Broadband (OTCMKTS: AABB) On the Move Northbound Since Sub $0.08 Dip as Crypto Innovator Elevates AABB Crypto Exchange & Enters the NFT Space

-

Uncategorized2 years ago

Uncategorized2 years agoMeta Materials Inc (OTCMKTS: MMTLP) Short Squeeze S-1a4 Filing Signals S1 Approval Could Be Days Away (Next Bridge Hydrocarbons Spin-Off)

-

BioPharma3 years ago

BioPharma3 years agoHumbl Inc (OTCMKTS: HMBL) Major Reversal as Powerful Advisor Rejoins the Team & Looks to Uplist to Major Exchange